As the manufacturing sector continues to evolve, consumers and business leaders all over the world are witnessing the emergence of smart factories. These facilities are characterized by their use of technology to improve efficiency and consistency in product quality.

Smart factories are making a significant impact on the way products are made and creating new opportunities for workers. Here’s a closer look at the rise of smart factories and how they are changing the manufacturing industry.

What is a Smart Factory, and How Does it Work?

In a nutshell, a smart factory is a facility that uses advanced technology to improve manufacturing processes. This can include everything from using sensors and data analytics to automate production line tasks to using virtual reality (VR) and augmented reality (AR) to train workers.

Smart factories are designed to be more efficient than traditional factories, and they often use less energy and water while producing fewer emissions. In addition, smart factories can be more flexible than conventional factories, as they can be quickly reconfigured to create different products.

Suppose you started using depth camera solutions to automate your factory’s inspection processes. You could use the same cameras and software to inspect products for defects, track inventory, and guide robots without needing to purchase separate equipment or hire extra workers. As a result, you would save time and money while reducing your environmental impact.

The Benefits of the Smart Factory Revolution

In the past, factories were often dirty, noisy places with heavy machinery operators. But with the rise of smart factories, that is all changing. Thanks to technology, factories are becoming cleaner and quieter, and workers can now operate machines using tablets and other devices. There are many benefits of smart factories, both for workers and the environment, such as:

Benefit #1: Improved Product Quality

Smart factories can produce products that are more consistent in quality thanks to advanced technology. For example, suppose a traditional factory has a batch of products, and each product is slightly different in terms of size or color.

In a smart factory, you can use sensors and data analytics to identify which products are not meeting the desired specifications. The products can then be fixed or removed from the production line before being shipped to customers. As a result, smart factories can produce more consistent yields, often essential for meeting customer expectations.

Benefit #2: Enhanced Worker Safety

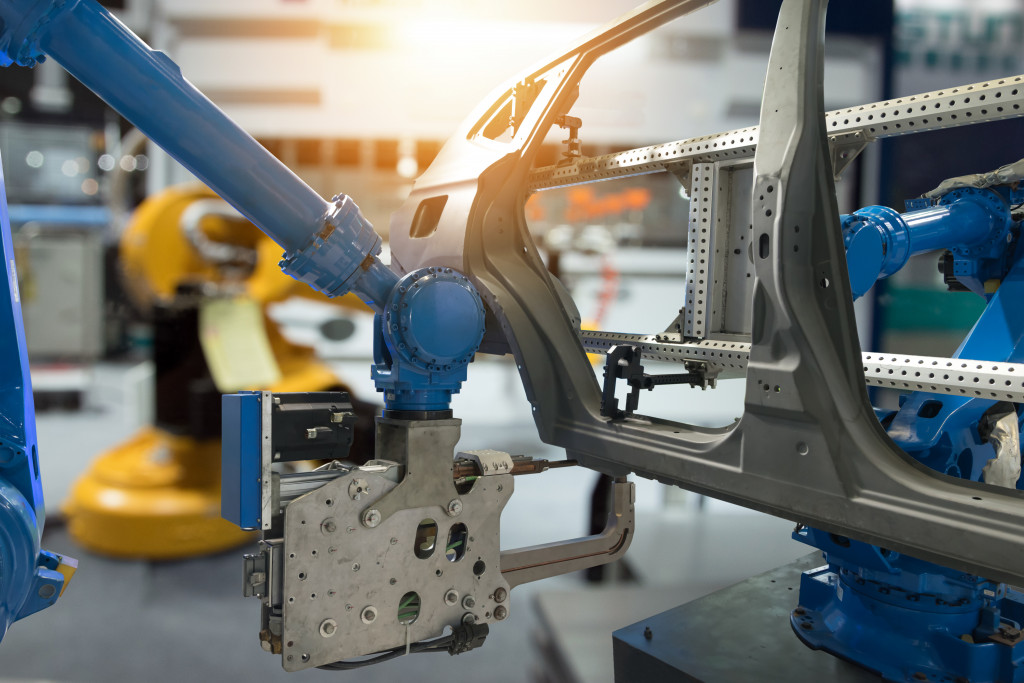

Smart factories are often designed with worker safety in mind. For example, many smart factories use robots to handle tasks too dangerous for humans, such as lifting heavy objects or working with hazardous materials. This means that the workers are less exposed to risks, leading to fewer accidents.

In addition, smart factories often use sensors and data analytics to track worker safety data. This data can be used to identify potential hazards and make changes to the factory floor to improve worker safety.

Benefit #3: Increased Efficiency

Smart factories are often more efficient than traditional factories because of the advancements in modern technology. For example, sensors and data analytics can help factories identify production bottlenecks and make changes that can improve efficiency.

Additionally, smart factories often use robots or automated machines to handle time-consuming or repetitive tasks. This can free up workers to address other more critical tasks, increasing efficiency.

Benefit #4: Reduced Environmental Impact

Smart factories often have a reduced environmental impact, thanks to modern technology. For example, sensors and data analytics can help factories reduce their energy consumption since they can identify areas where energy is being wasted.

Furthermore, smart factories often use recycled materials or renewable energy sources, further reducing their environmental impact. This means that smart factories can produce a smaller carbon footprint than traditional factories.

The Future of the Manufacturing Sector

The manufacturing sector is undergoing a significant transformation thanks to the rise of smart factories. This shift is making factories more efficient and helping them produce products that are more consistent in quality — ultimately benefiting both workers and the environment.

In addition, smart factories are also creating new opportunities for workers who can now work remotely and on flexible schedules. Although there is fear that many workers will be displaced because of automation, smart factories will likely create new jobs in the long term.

What does the future hold for smart factories? Only time will tell, but one thing is for sure: the rise of smart factories will significantly impact the manufacturing sector for years to come. So, don’t be left behind — embrace the change and make your factory a smart one today.