Motors are more versatile and adaptive than they’ve ever been. Motor selection is important when designing a motion control system. The motor must be compatible with the system’s function and overall performance goals. Fortunately, there is a motor design appropriate for each application.

Of course, there are more factors to consider than horsepower, speed, and torque when selecting the ideal motor for your application. This article highlights the different types of motors and their application for business devices.

AC Motors

AC motors are electromechanical devices that create rotational motion using an alternating current. The rotation generates mechanical energy, which is used to power other spinning machinery like pumps.

AC motors, typically operate fans, pumps, compressors, and other devices, account for a considerable percentage of all motors in use today. Machines range in size from sub-fractional horsepower to 20,000 HP more, with metric units available as well.

AC motors are used for various applications such as:

- Pumps

- Water heaters

- Lawn and garden equipment

- ovens

- off-road motorized equipment

Air Motors

Air motors are mechanical devices that create rotational motion using air pressure, which is used to power other rotating machines like take-up reels and tools.

Air motors are used where a supply of compressed air is available and a constant torque independent of speed is required, such as the scrap take-up reel on a packing machine.

Air motors are used for various applications such as:

- Dental drills

- Tire changers

- Torque wrenches

- Drills

- Grinders

- Die grinders

- Sanders

DC Motors

DC motors are electromechanical devices that provide rotational motion using direct current. The motion generates rotational energy that is used to power other rotating equipment, such as hoists, at different speeds. Certain wire arrangements can provide significant slow-speed torque, making them appropriate for use as locomotive traction motors.

DC motors are used for various applications such as:

- Toys

- Automobile manufacturers

- Elevators

- Electric forklifts

- Rolling mills

- Conveyors

- Sewing machines

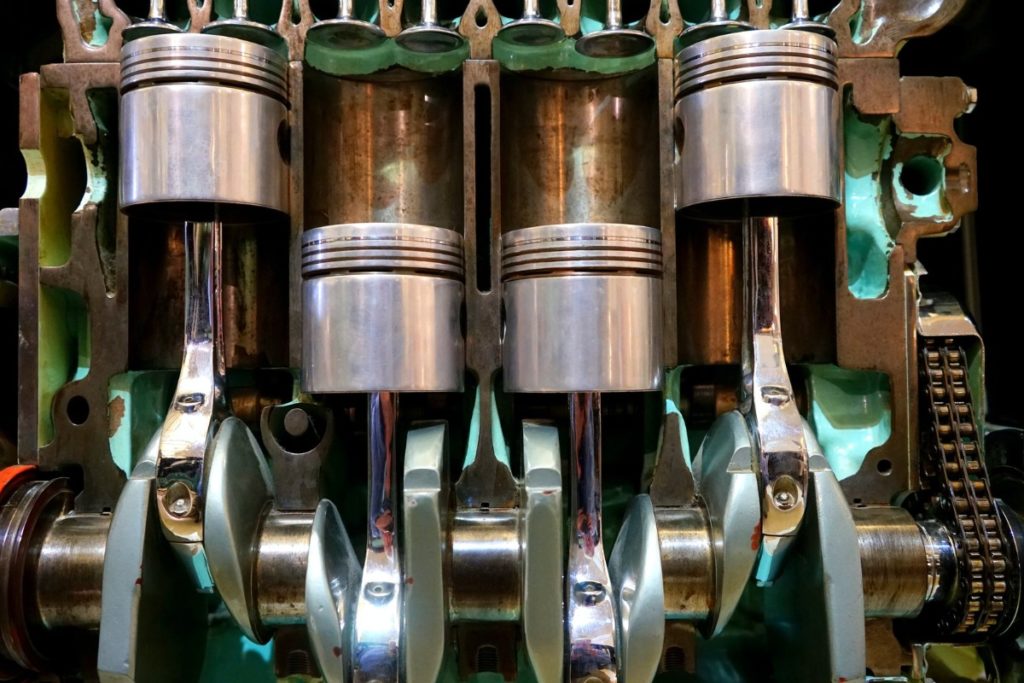

Hydraulic Motors

Hydraulic motors are rotating mechanical devices that are driven by fluid. The motion provides rotational work for other rotating parts, such as a heavy-equipment excavator’s driving wheels. Hydraulic motors are widely utilized in construction machinery where a small device with rotating motion is required and hydraulic power is already available.

Hydraulic motors are used for various applications such as:

- Hydraulic pumps

- Vane

- Gear

- Piston-driven

Gearmotors

Gearmotors are electromechanical devices that provide rotational motion using alternating or direct electricity. The motion generates rotational work, which is subsequently stepped down to drive other rotating devices like conveyors or packing machines through an integrated gearhead.

When motors and speed reducers are required to create high torque at low speeds, gearmotors are utilized. They are available in a variety of output shaft designs and motor types, including AC, brushed- and brushless-DC motors.

Gearmotors are used for various applications such as:

- Automotive; power winches on trucks and windshield wiper motors

- Jacks

- Cranes

- Lifts

- Clamping

- Robotics

Stepper Motors

Stepper motors are electromechanical devices that create rotational motion and positioning using alternating current. Stepper motors do not have a feedback loop and instead provide position control by turning the motor rotor a discrete number of steps.

A stepper linear actuator with a fixed leadscrew is a basic stepper motor that converts the rotational motion in the form of discrete steps into linear motion. The cost of developing a separate transmission mechanism in the system is eliminated by achieving linear motion within the motor.

Stepper motors are used in positioning applications where maintaining a position is important such as packing machines, printers and other equipment where losing position due to overload is not vital and the cost is a consideration.

Stepper motors are used for various applications such as:

- 3D printing equipment

- Slot machines

- Medical imaging machinery

- Flatbed scanners

- Intelligent lighting

- Small robotics

- Welding equipment

Servomotors

Servomotors are electromechanical devices that create rotational motion and positioning using alternating or direct current. A feedback loop is used in servomotors to regulate the radial position of the motor rotor in relation to its stator.

For example, servomotors are used in situations where smooth, regulated motion is important, such as an industrial robot and a packing machine may employ a servomotor to index a precise amount of packing film into a forming zone, while such feeding could previously have been controlled by a motor-driven mechanical indexer.

Servomotors are used for various applications such as:

- Milling machines

- Robotics

- Lathes, grinding, punching, pressing and bending in metal fabrication

Rotary motion is provided by AC, DC, gear, air, and hydraulic motors, while positioning is provided by stepper, servo, and linear motors. An AC motor is the most common choice for driving a pump; a DC motor is a good fit for driving a crane drum when variable speed is needed; gearmotors perform the same functions as bare AC and DC motors but have inherent gear reductions, and air and hydraulic motors cover comparable demands in circumstances where electricity is neither practicable nor appropriate.